0262

- Industry General Industry

- Problem Corrosion / Erosion and Cavitation

- Country Germany

-

Project Goal

To rebuilt the Francis turbine vanes from erosion/corrosion and repair the effects of cavitation

- Products Used CeramAlloy CL+AC, CeramAlloy CP+AC, and DuraTough DL

- Status Completed

German utility company repairs and protects cavitation damage on francis turbine with CeramAlloy & DuraTough

Problem: Francis turbine vanes were suffering from erosion and corrosion due to the effects of cavitation after the failure of a previously applied coating.

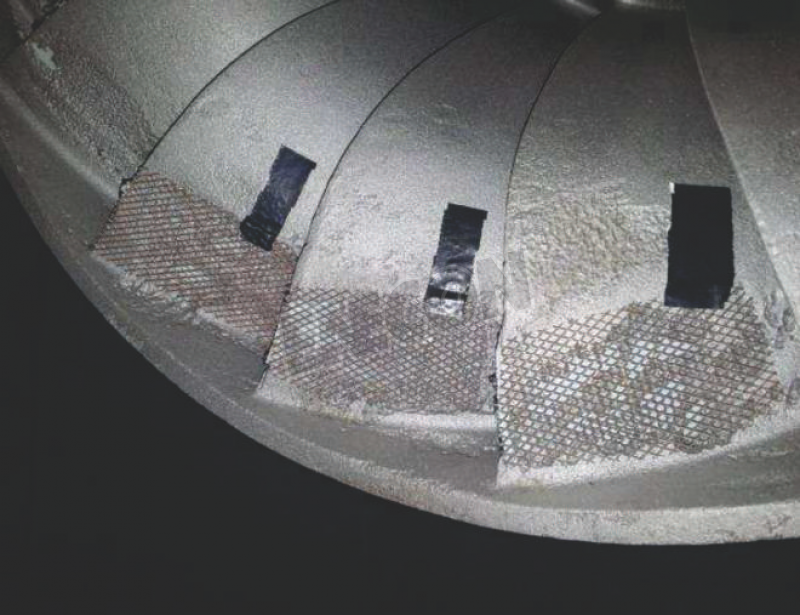

Solution: After grit blasting the turbine, the vanes were rebuilt by tack welding steel mesh to the deeply cavitated areas. The vanes were then rebuilt with CeramAlloy CP+AC then two coats of CeramAlloy CL+AC were applied. DuraTough DL was applied to protect against future cavitation problems.

After operating for 7,000 hours, the repaired turbine was opened for an inspection and found to be in near perfect condition.

1. Steel mesh is welded to the vanes.

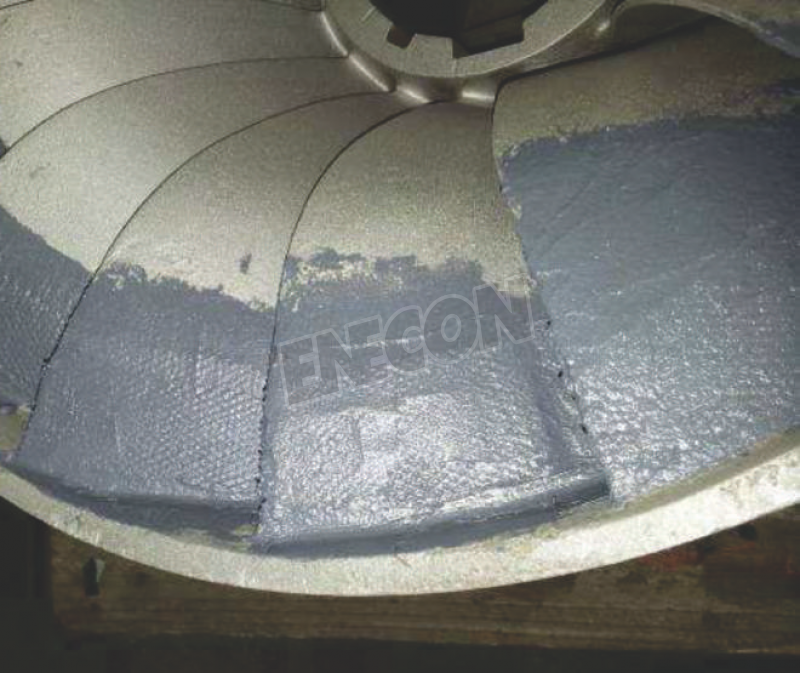

2. CeramAlloy CP+AC covers the mesh repairs.

3. CeramAlloy CP+AC rebuilds the vanes.

4. The turbine is coated with CeramAlloy CL+AC.

5. DuraTough DL provides the cavitation protection.